- The principle of sublimation printing

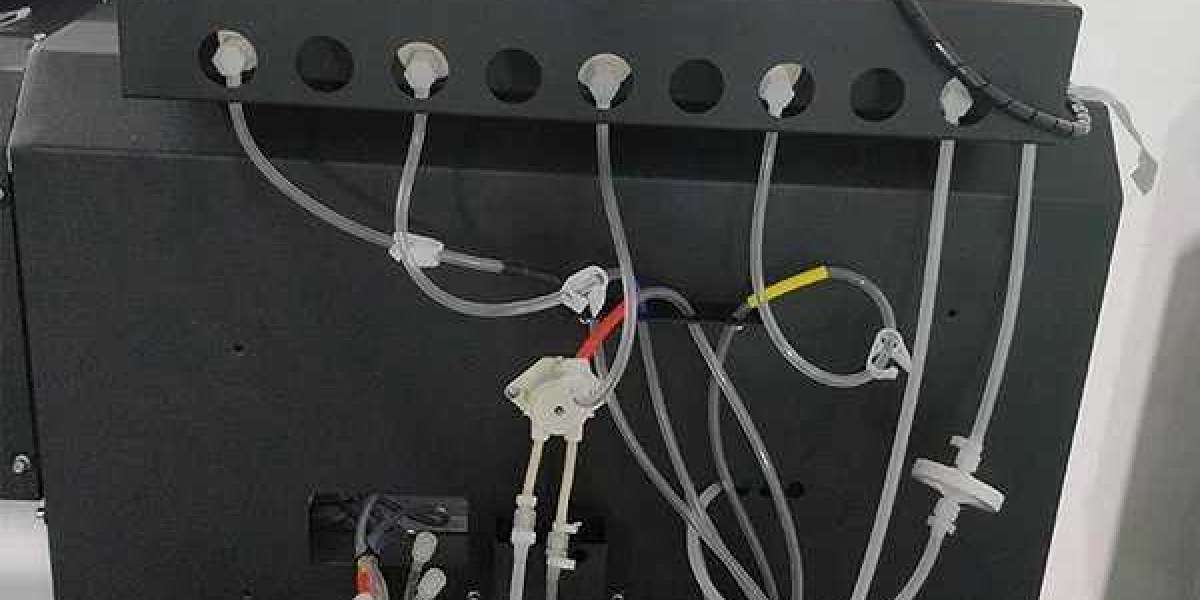

Dye-sublimation printers work by placing solid pigments of four colors (cyan, magenta, yellow, and black) on a drum on which tens of thousands of semiconductor heating elements are installed. When the temperature is raised to a certain level, the solid pigment can be directly converted into a gaseous state, and then the gas is sprayed onto the printing medium. Each semiconductor heating element can be adjusted to 256 temperatures, allowing the ratio and shading of colors to be adjusted for true-color photos with continuous tone. Dye sublimation technology uses heat energy to transfer pigments to the printing medium, and the intensity of each color is controlled by the temperature change of the print head. Because the pigments are vapor-applied to the paper through a sublimation process, the three primary colors fuse with each other to form a continuous gradation, which is much better than inkjet-printed droplets. Some dye-sublimation printers also have a film attachment process after three coloring. That is to say, the special material on the ribbon is sublimated and attached to the paper surface on the three-layer color to form a protective film, which can play the role of anti-oxidative discoloration, waterproof, anti-fingerprint and so on. This is something that inkjet printers cannot do.

Advantages of Dye Sublimation Printing

In terms of color expression, dye-sublimation printers are much better than ink-jet printers. The precision of 300dpi of dye-sublimation printers is almost equivalent to the effect of 4800dpi of ink-jet printers. Moreover, it can combine the proportions and shades of colors through the different temperatures adjusted by each semiconductor element on the ribbon to achieve a continuous-tone color photo effect. Therefore, in terms of photo printing quality, the color fidelity and reproducibility of images printed by dye-sublimation printers are better than those of inkjet printers and color laser printers; the coating function is a unique function of dye-sublimation printers. Since the sublimation printer is mainly used to print photos, after the photos are coated, the overall color feeling will be brighter and brighter, and it also has the functions of water release and anti-oxidation, which is better than the traditional inkjet in preservation. Photos from the printer will take longer.

- DTF printing paper produced by Langlang

Suzhou Jiuyuan Digital Technology Co., Ltd. is a professional paper mill. Our main product is sublimation paper. We have two high-speed coating machines with a width of more than 3200mm, which can output more than 6000 tons of sublimation paper per month. Our address is in Building 1, Midu Village, Weitang Town, Xiangcheng District, Suzhou City. If you are interested in our company and want to cooperate, you can contact: 0086-18912615950